Dr. Heinz-Jakob Neußer, Member of the Board of Management for the Volkswagen brand with responsibility for Development and Volkswagen Group Head of Powertrain Development, concluded this year’s International Vienna Motor Symposium by providing an outlook of the future of mobility and innovative technologies. The biggest challenges facing the industry are reducing CO2 emissions, electromobility and digitalisation.

At the symposium, Friedrich Eichler, Head of Powertrain Development for the Volkswagen brand, also presented the new 6.0 W12 TSI. The new EU6 TDI engine family for light-duty vehicles was presented by Jörn Kahrstedt, Head of Diesel Engine Development for the Volkswagen brand.

In his concluding presentation, Dr. Neußer stated that the industry had changed more rapidly and more extensively in the last few years than in the preceding decades. However, environmentally friendly mobility remains the key topic for the automotive industry. “Climate protection is an integral part of our responsibility towards people and society. Moreover, customers demand models with reduced consumption and lower emissions and politics also makes high demands on the automotive industry”, Dr. Neußer continued.

The wide range of powertrains within the Volkswagen Group – ranging from petrol and diesel engines to natural gas vehicles, plug-in hybrids, purely electric cars and potentially even fuel cell cars – shows the Group’s enormous innovative strength. The Management Board Member in charge of development emphasised that: “The optimisation of the internal combustion engine is still an important field of innovation. High-efficiency TDI and TSI/TFSI engines – ideally in combination with DSG – will remain indispensable for the foreseeable future. The reduction of CO2 emissions from internal combustion engines is pure high-tech nowadays. Examples of this are our high rpm diesel as well as the high-performance three-cylinder TSI engine.”

Dr. Neußer highlighted the fact that the high rpm diesel points the way to the future of the internal combustion engine in many respects. With high-efficiency combustion methods, innovative thermal management, maximal charging thanks to e-boosters as well as new materials and coatings, these state-of-the-art TDI engines are already capable of achieving a power output of well over 100 kW per litre of displacement.

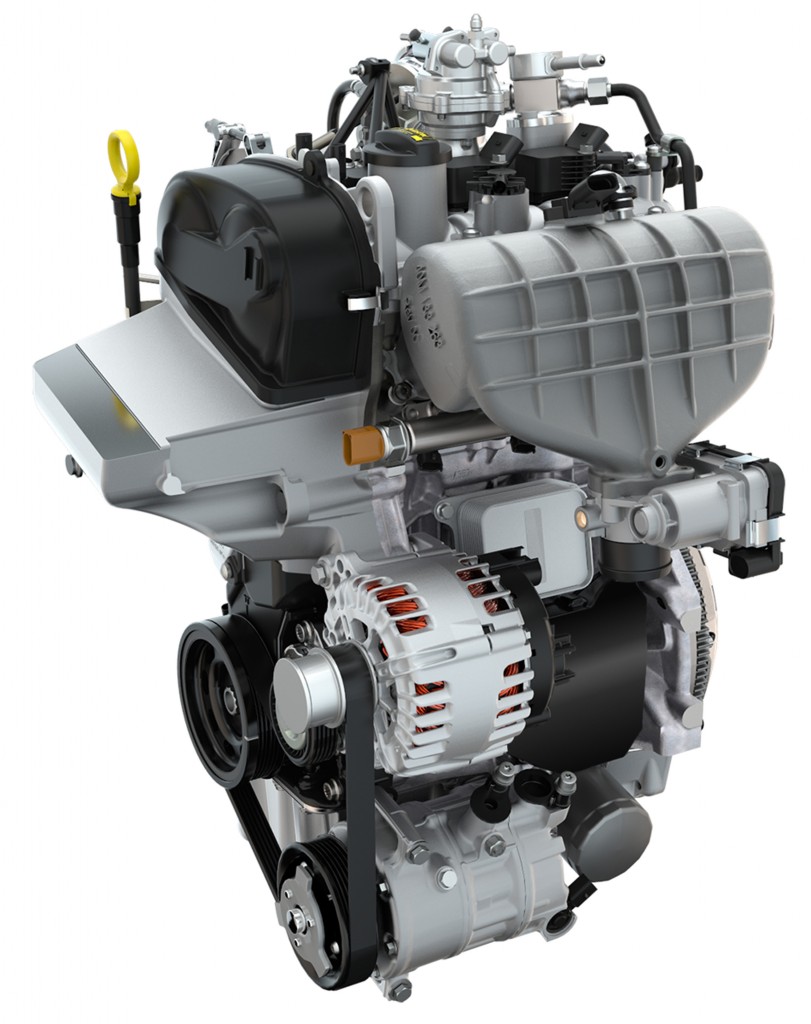

In the field of petrol engines, Dr. Neußer offered a glance at the high-performance three-cylinder TSI based on the EA211 engine. With the genes of the Polo WRC’s rally engine, this power unit is capable of generating 272 PS and 270 Nm of torque from just one litre of displacement thanks to a monoscroll turbocharger and e-booster. “A nice example of just how much potential combustion engines still have in them”, according to Dr. Neußer.

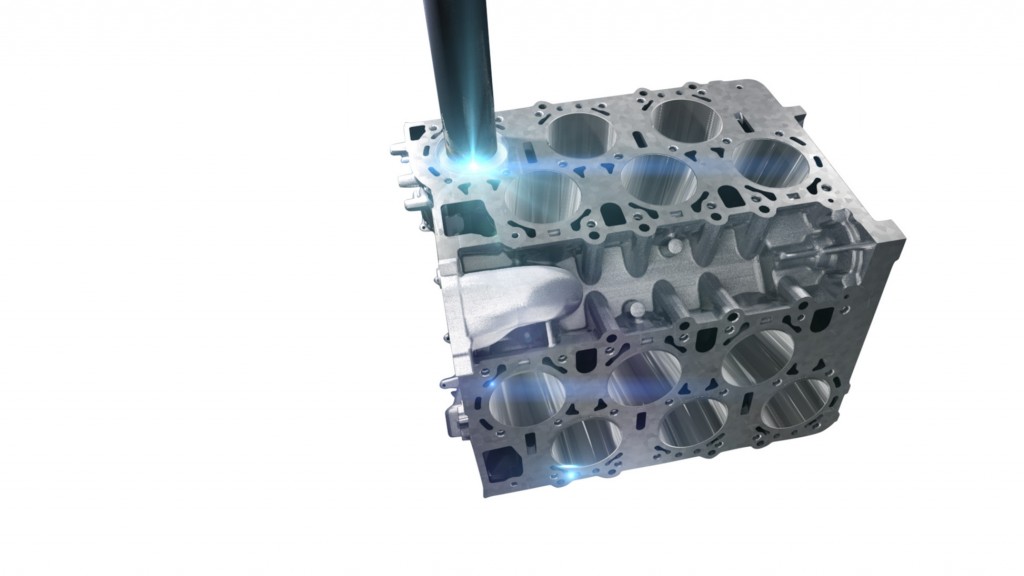

Dr. Neußer also gave a peek at “laser roughening”. This coating technique, which the Volkswagen Group will use in large-scale production in future, contributes significantly to reducing friction in the engine and to boosting performance. Dr. Neußer pointed out that this is an important innovation in manufacturing technology, since laser roughening not only reduces tool wear to zero, but also achieves consistent results and can be used for all materials.

Dr. Neußer sees digitalisation as the greatest challenge, because infotainment, assistance systems and networking have come to be at least as important to many customers as the engine performance. “The Golf R Touch concept car has everything on board that characterises the cockpit of the future: full connectivity thanks to the integration of apps, smartphones, tablets and smart watches, as well as large touchscreens and, last but not least, gesture control, which opens the sunroof at a wave of the hand. Over and above this, we are also pushing the envelope when it comes to automatic or piloted driving and are working on new business models and a range of digital services relating to our cars. So I am sure that the car of the future will continue to fascinate people just as much as it ever has.”

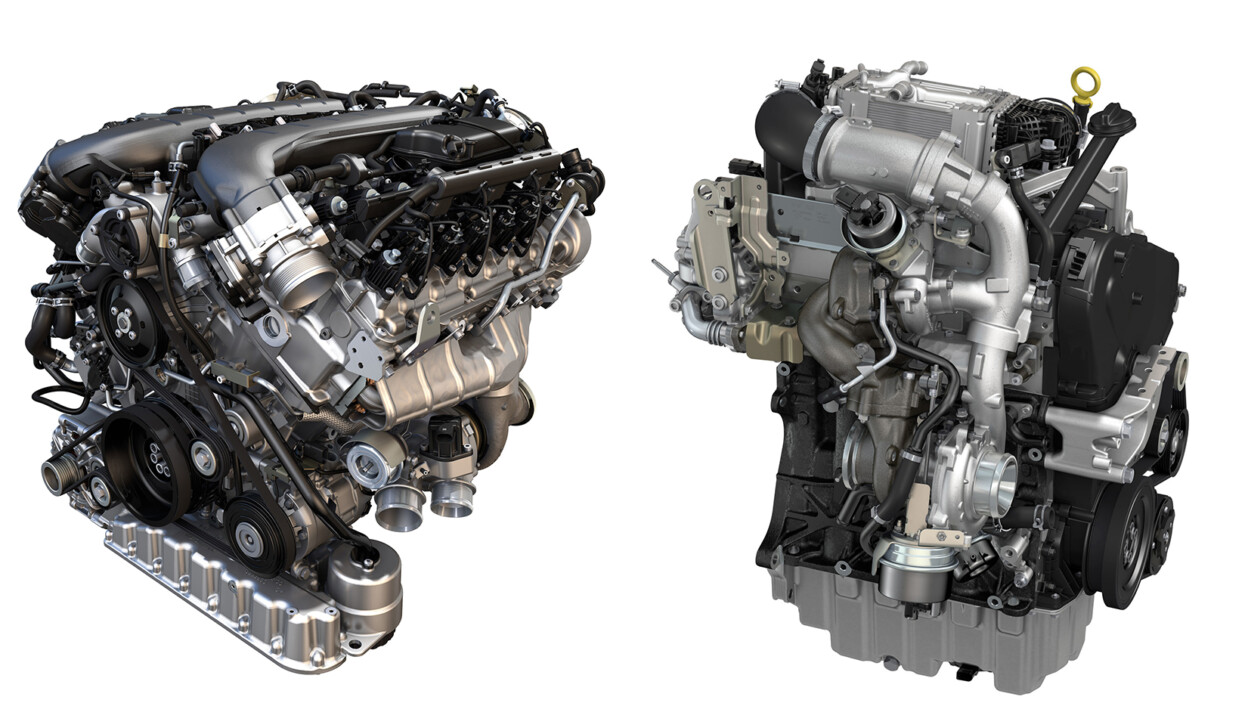

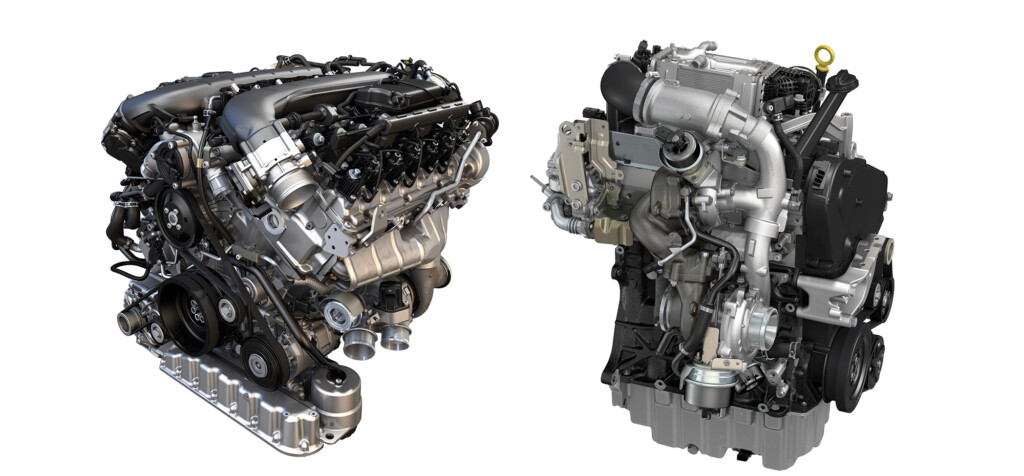

A few hours earlier, Volkswagen had already presented its latest generations of engines at the International Vienna Motor Symposium, which is held annually by the Austrian Society of Automotive Engineers (ÖVK), chaired by professor H.P. Lenz from the Vienna University of Technology: the new W12 TSI, as one of the most demanding premium engines in the world as well as the new 2.0 litre TDI EU6 diesel engine for light-duty vehicles. The talk about the new twelve-cylinder engine was given by Friedrich Eichler, Head of Powertrain Development for the Volkswagen brand, while the new family of diesel engines was presented by Jörn Kahrstedt, Head of Diesel Engine Development for the Volkswagen brand.

The new 6.0 litre W12TSI for the Volkswagen Group’s premium models

Based on the W12 concept, the Volkswagen Group has deployed top-of-the-range engines that have demonstrated their perfection in terms of performance and comfort in the premium models made by the Volkswagen, Audi and Bentley brands in an impressive manner for some 13 years now. The next generation W12 TSI presented at this year’s Motor Symposium makes the Volkswagen Group’s cutting edge engine one of the most fascinating power units with the highest technology density in the world.

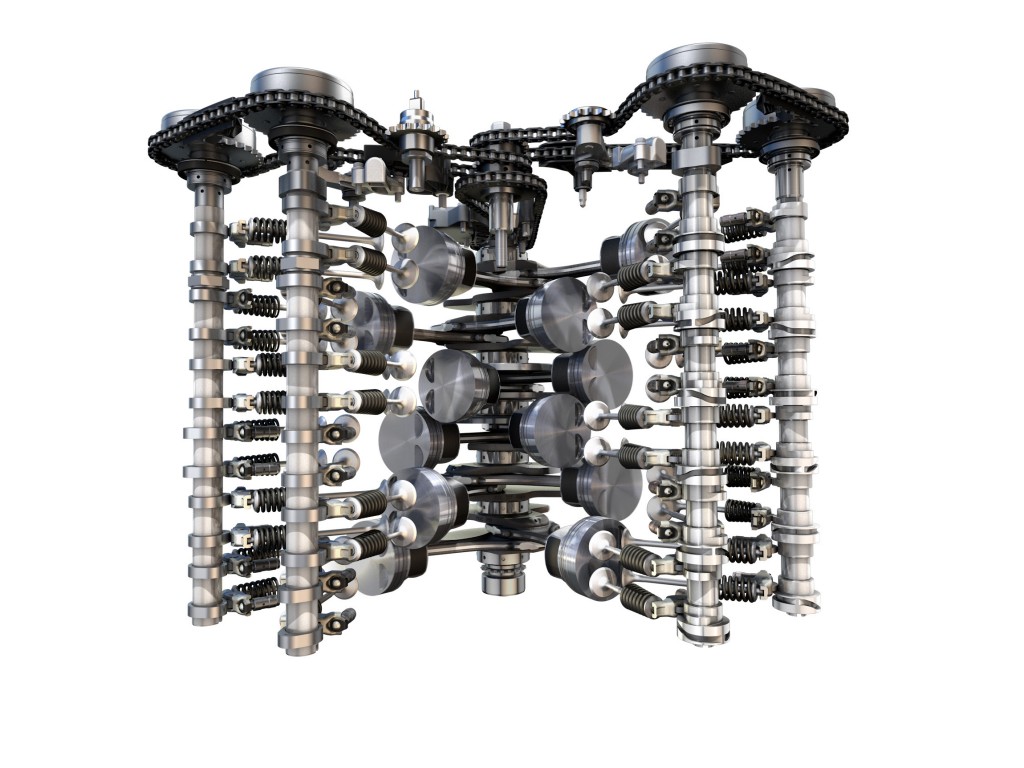

For example, as part of the improvements and new developments, two combustion methods that have to date been used in parallel – Audi’s FSI direct injection and Bentley’s TMPI multi-point injection – were combined, together with other new or optimised systems and components, to form the successful TSI process. The scope of development also included cylinder bores with APS coating, an oil circuit suitable for off-road use with a switchable oil pump, a cooling system with integrated temperature management, dual fuel injection with high pressure direct and low pressure manifold injection, twin-scroll biturbo charging, individual cylinder bank deactivation (on the left in the direction of travel), engine management with two controllers as well as a start/stop system that reduces fuel consumption and emissions. Adaptive engine suspension with hydraulic basic damping, which uses electromagnetic actuators to counteract vibrations induced by the engine with phase-shifted counter-vibrations, contributes to the premium-quality driving comfort.

The technological elements used make the new W12 TSI the most economical twelve-cylinder engine in the luxury car segment. CO2 emissions of less than 250 g/km in the New European Driving Cycle (NEDC) – at a power of 447 kW/608 PS (6,000 rpm) and a maximum torque of 900 Nm (1,500 – 4,500 rpm) – demonstrate impressively how efficiency and performance of the highest standard are combined in this engine. Depending on the vehicle model, the 6.0 l twelve-cylinder engine delivers acceleration values of 0 to 100 km/h in less than four seconds and top speeds of over 300 km/h.

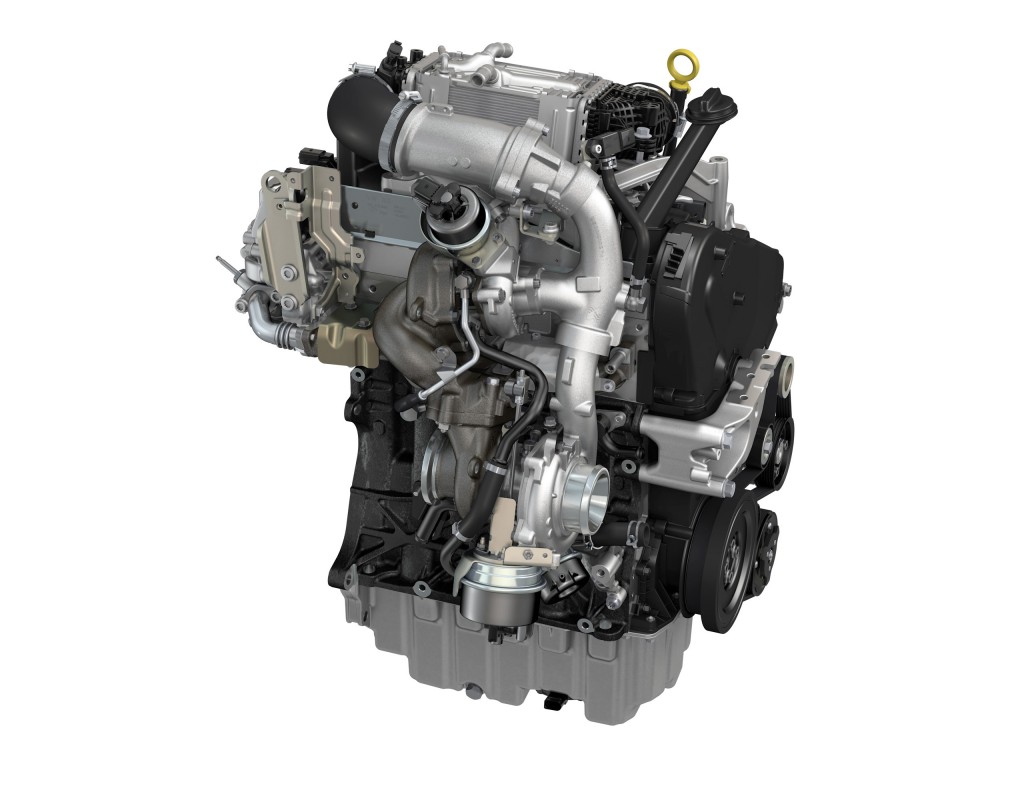

The new 2.0 litre TDI diesel engine for light-duty vehicles

The newly developed 2.0 TDI 4V engine, based on the modular diesel component system (MDB), makes its debut with the market launch of the new Multivan and Transporter models from Volkswagen Commercial Vehicles. The new family of engines is tailored to the requirements of commercial vehicles, while also extending the power range.

During their development the focus was on a significant reduction in fuel consumption (by 14 percent, on average) while simultaneously meeting the EU6 emission limits, as well as a traction capacity oriented torque curve with a noticeable increase in driving performance for the customer. Moreover, the top-of-the-range engine features a newly developed dual-stage turbocharger layout.

To undercut the legal requirements for NOx and particle raw emissions for the EU6 emissions standard, it uses not only a common-rail system with 2,000 bar injection pressure, but also a new low-temperature/high-pressure exhaust gas recirculation system and a water-cooled charge air cooler. In addition, a variable intake manifold guarantees the necessary flow swirl when running at partial load. Exhaust gas aftertreatment is accomplished by an oxidation catalyst with a downstream combination of diesel particulate filter and SCR catalytic converter.

At present, four versions of the engine cover a power range of 62 kW (84 PS) to 150 kW (204 PS) and a torque range of 220 to 450 Nm. With a specific power output of over 76 kW and a specific torque of over 225 Nm per litre of displacement (plus approx. 13 percent), this new Transporter engine is the “benchmark” in its segment. The starting torque has also increased disproportionately, which clearly demonstrates the advantages of the VTG high-pressure stage within the biturbo charging unit.

Best-in-class values in terms of driving enjoyment and driving dynamics – alongside adequate power – are ensured by beefy torque curves and superior move-off characteristics over the entire rpm range, with a turbocharger with variable turbine geometry (VTG) being used for the performance levels up to 110 kW. For the top-of-the-range engine with 150 kW, the existing two-stage charging was completely redesigned and augmented by another variable turbine geometry in the high pressure stage.

Other posts by AF Newsdesk