Ford Motor Company will chart new territory as the company seeks to create adhesive innovations inspired by the gecko.

For many years, Ford researchers have considered ways to make auto manufacturing more sustainable. One main challenge was the glue used to adhere foams to plastics and metals can make disassembling parts for recycling nearly impossible.

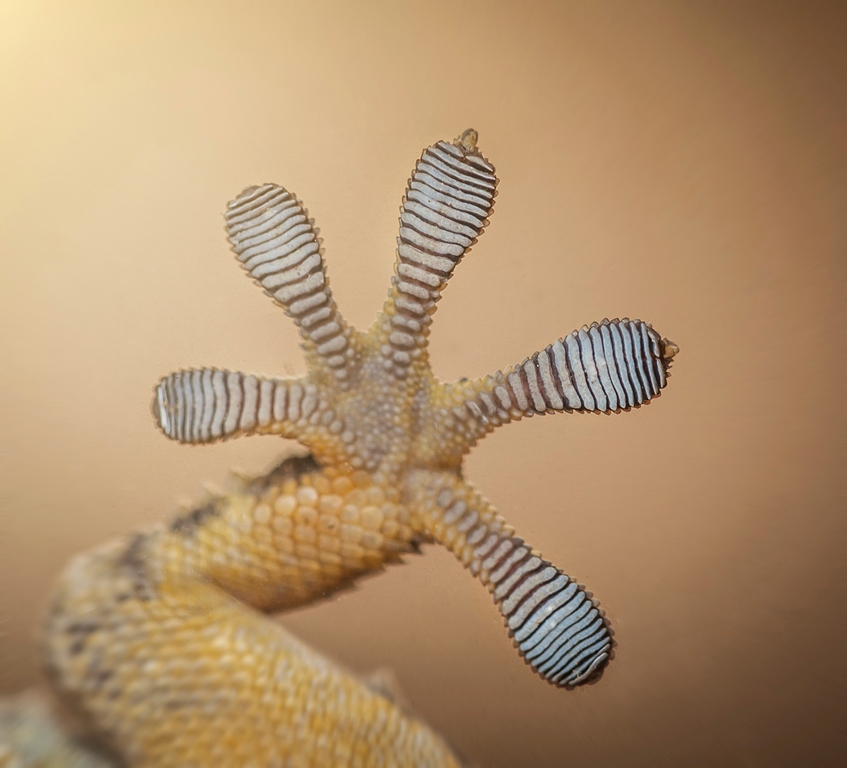

That is, until Ford looked at the gecko. The little gecko’s toe pad allows it to stick to most surfaces without any surface tension. If needed, the lizard can easily release itself without leaving any residues. Also, a typical gecko weighing 2.5 ounces can support up to 293 pounds.

Ford will work with Procter and Gamble to work on a host of adhesive innovations for gloval applications at Ford. “Solving this problem could provide cost savings and certainly an environmental savings,” said Debbie Mielewski, Ford senior technical leader for plastics and sustainability research. “It means we could increase the recycling of more foam and plastics, and further reduce our environmental footprint.”

“We are excited for the opportunity to participate, together with Ford – with whom we have a history of collaboration – in The Biomimicry Institute workshop,” said Lee Ellen Drechsler, director for corporate connect and development, The Procter and Gamble Company. “We have an interest within Procter & Gamble for using biomimicry as a way to broaden our approach to solving tough research challenges.”

Using animals as inspiration is not new. The Bullet Train in Shinkansen, Japan was inspired by the kingfisher. Velcro took its cues from a burr. And improved medical needles were developed based on the mosquito.

Other posts by AF Newsdesk