Big news from Proton! The company has officially started building its first-ever EV production plant at its cutting-edge Tanjung Malim facility. With a hefty investment of RM 82 million, this milestone marks a bold step into the future of electric mobility.

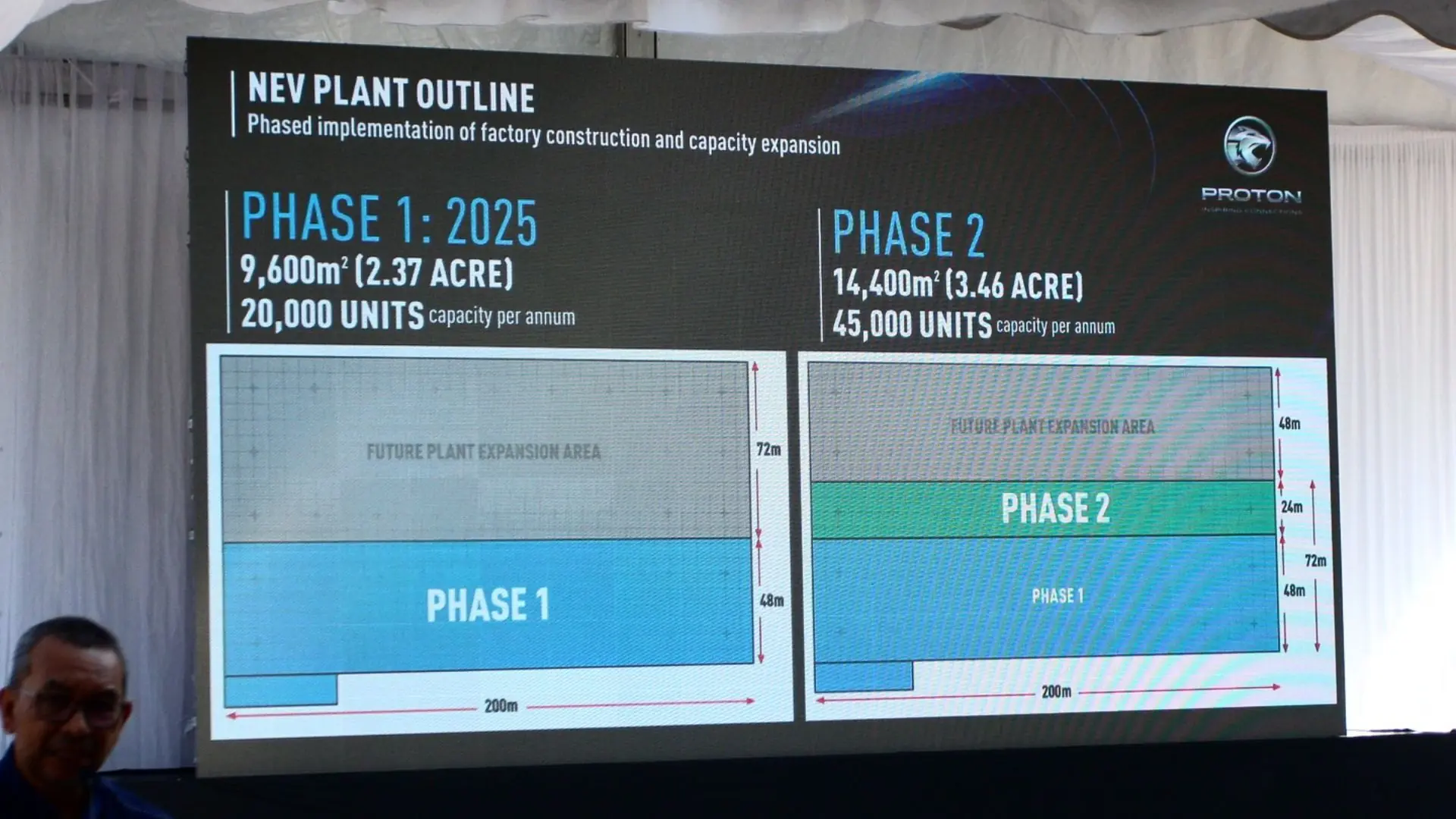

The first phase of construction is set to wrap up by the end of the year, and once fully operational, the plant will have the capacity to roll out 20,000 EVs annually.

A New Era for Proton EVs

This state-of-the-art facility will manufacture vehicles based on the Global Modular Architecture (GMA) platform from Geely, with Proton’s first fully electric model—the Proton e.Mas 7—leading the charge.

Speaking at the launch, CEO Dr Li Chunrong highlighted that the GMA platform is designed as the foundation for Proton’s next-gen models, with an exciting five-model EV lineup already in the works.

Grand Ceremony to Mark the Beginning

To celebrate the occasion, a grand groundbreaking ceremony was held today, attended by distinguished guests, including Perak Menteri Besar Datuk Seri Saarani Mohamad, Proton board member Ahmad Jauhri Yahya, Dr Li Chunrong, and Deputy CEO Roslan Abdullah. The event was a testament to Proton’s commitment to innovation and sustainability in the automotive industry.

Aligning with Malaysia’s EV Vision

Proton’s foray into EV manufacturing isn’t just about building cars—it’s a crucial part of Malaysia’s EV industrialisation strategy. This project supports major national policies like the New Industrial Master Plan (NIMP), National Automotive Policy (NAP 2020), Low Carbon Mobility Blueprint (LCMB), and the New Energy Transition Roadmap (NETR).

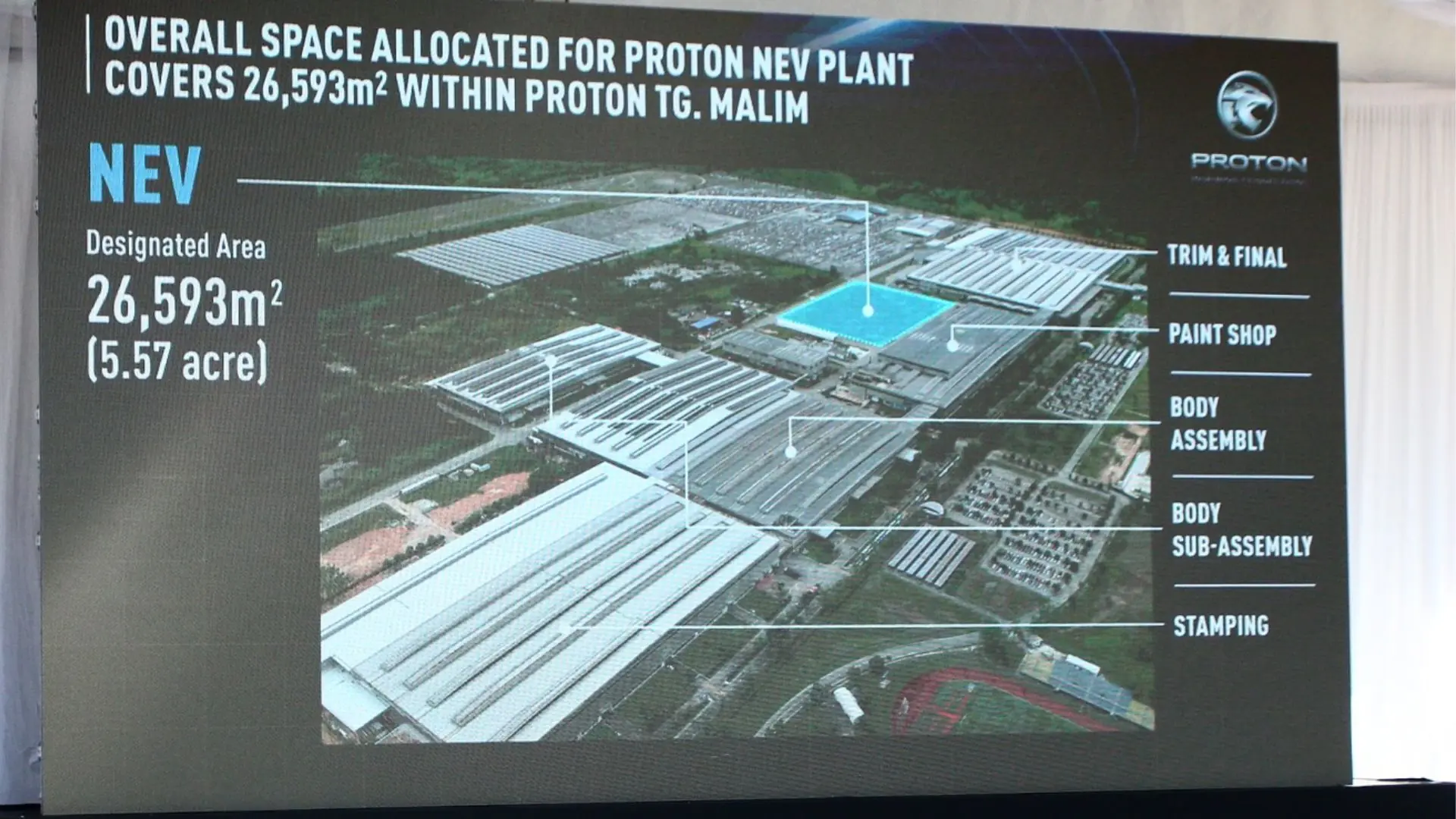

By consolidating all its manufacturing operations at Tanjung Malim, Proton is reinforcing the importance of the Automotive High-Tech Valley (AHTV), setting Malaysia up as a regional hub for EV innovation.

A Smart, High-Tech Future

Designed for New Energy Vehicle (NEV) production, the plant will feature cutting-edge Industry 4.0 technologies—think high automation, robotics integration, cloud-based management, and Industrial IoT.

These innovations will ensure efficient, high-quality production while keeping the environmental impact to a minimum. Despite automation taking centre stage, the facility is expected to create over 200 highly skilled jobs, bringing significant benefits to the local workforce.

Bigger and Better: Phase Two Expansion

As Proton gears up to meet growing EV demand in Malaysia and beyond, the company has already outlined a second phase of expansion. This will more than double the plant’s capacity to 45,000 units per year, with the scale-up set to align with market demand.

Looking ahead, Dr Li Chunrong expressed hopes that Proton’s success will inspire more OEMs to see Malaysia—and specifically AHTV—as a prime location for EV production in the region. With Proton making bold moves, Malaysia’s position in the global EV revolution is only getting stronger.

Source: Caricarz

Other posts by Keran