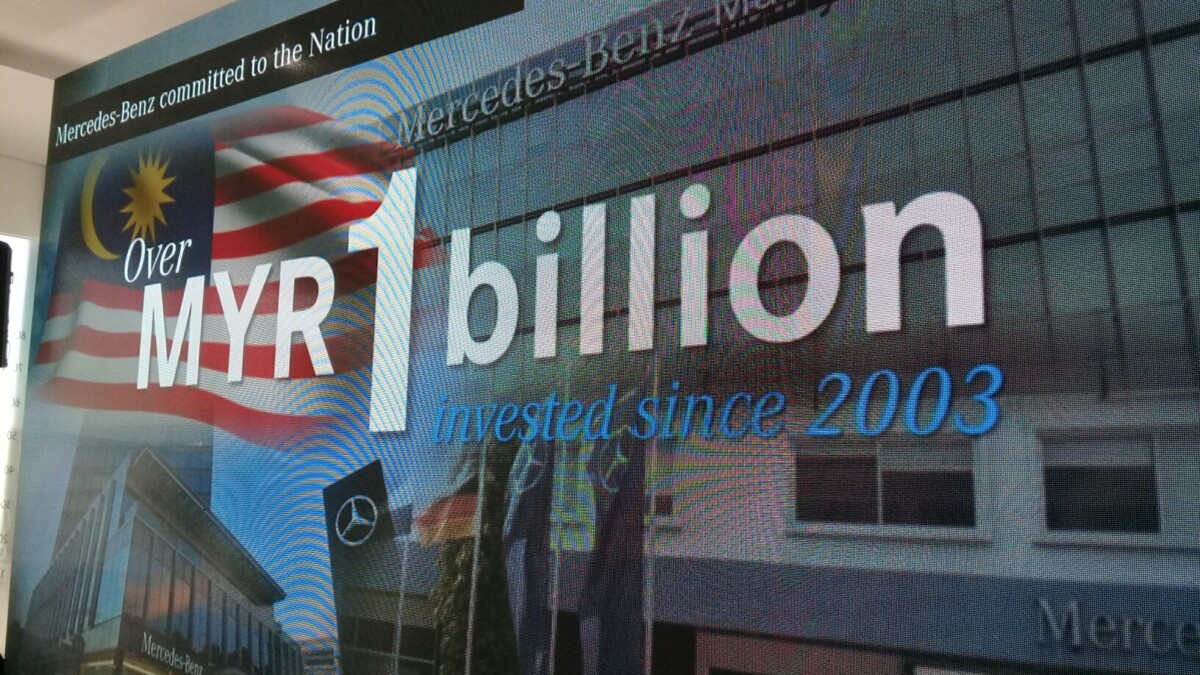

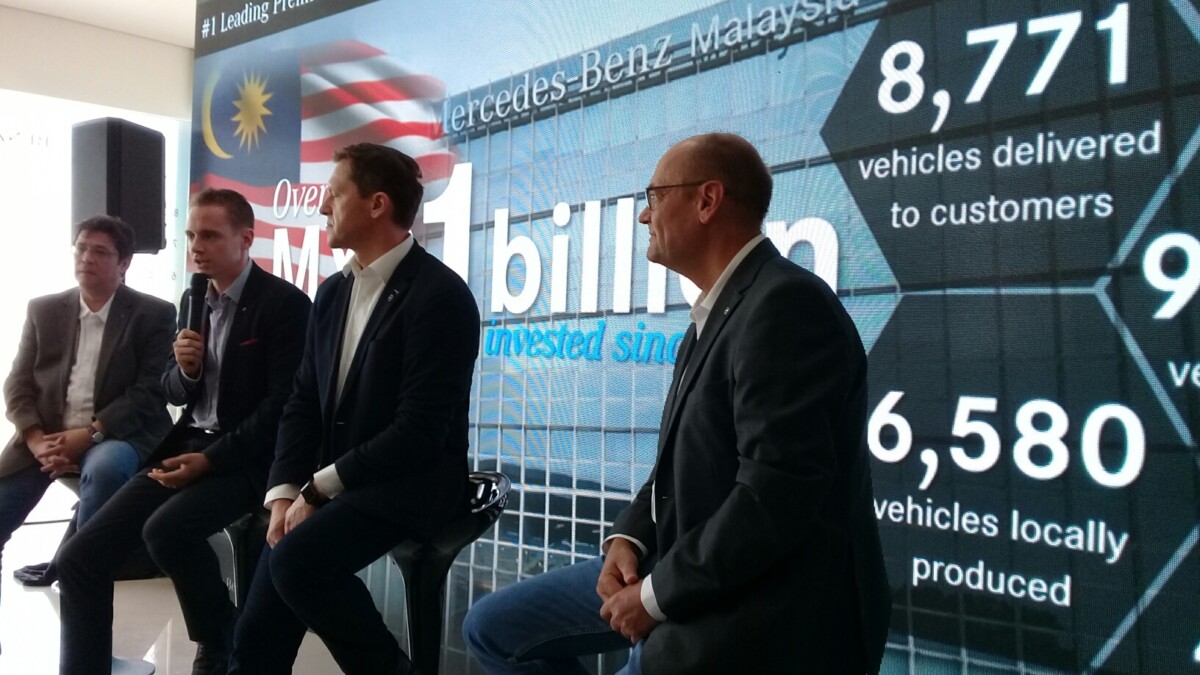

Yes, you read that right. Since its implementation in 2003, Mercedes-Benz Malaysia (MBM) has invested a total of more than RM 1 billion in the Malaysian market to-date.

With these investments, in the form of production, sales, training and distribution of Mercedes-Benz vehicles, the German marque has once again reaffirmed its stand as a long-term and committed investor keen on driving further growth in Malaysia.

“As the premium market leader, Mercedes-Benz Malaysia is confident of the growth potential in the Malaysian automotive market. Based on this positive outlook, we continue to invest substantially in developing key areas including talent, technology, production and service as well as providing further employment possibilities and people development. These investments in turn help us deliver the Best Products and the Best Customer Service through a consistent and high level of service and expertise to our customers and cement our position as the No. 1 premium brand,” said Mercedes-Benz Malaysia President & CEO, Dr Claus Weidner (above, right).

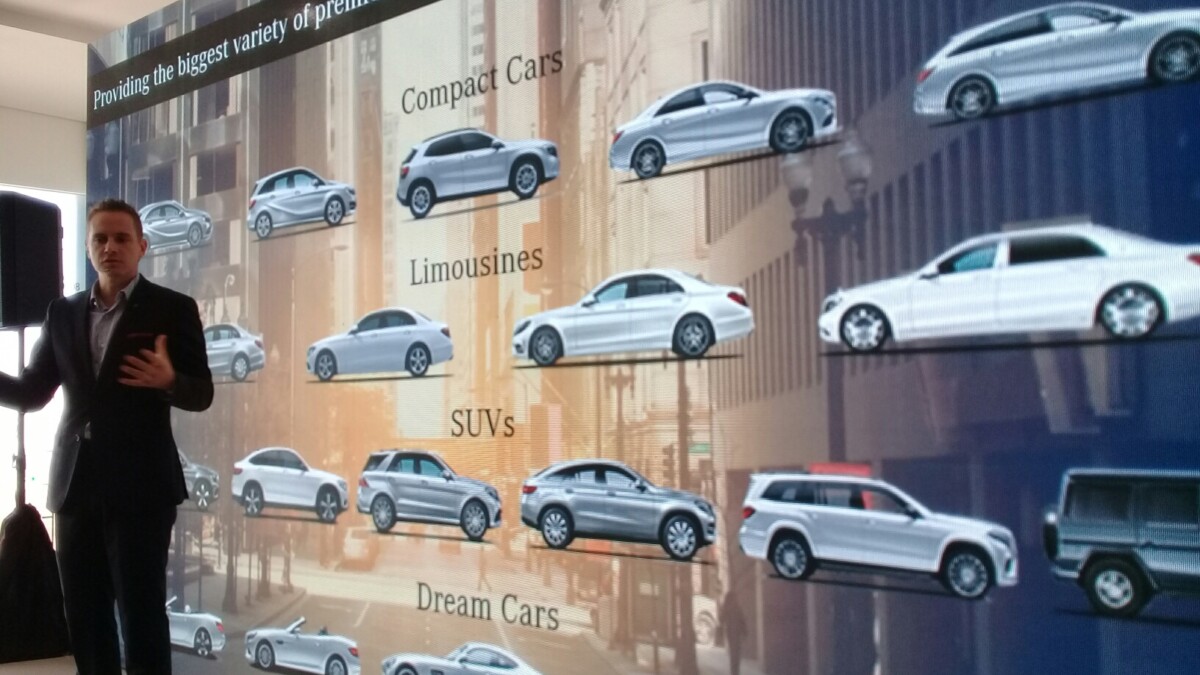

“Mercedes-Benz continues to lead in the premium segment. With the product expansion strategy, launching 13 new models and Best Customer experience offensive, with eight new and upgraded dealerships over the past nine months, MBM was able to deliver 8,771 vehicles to customers, on track for yet another record year in 2017,” said Mercedes-Benz Malaysia Vice-President for Sales & Marketing, Mark Raine (above).

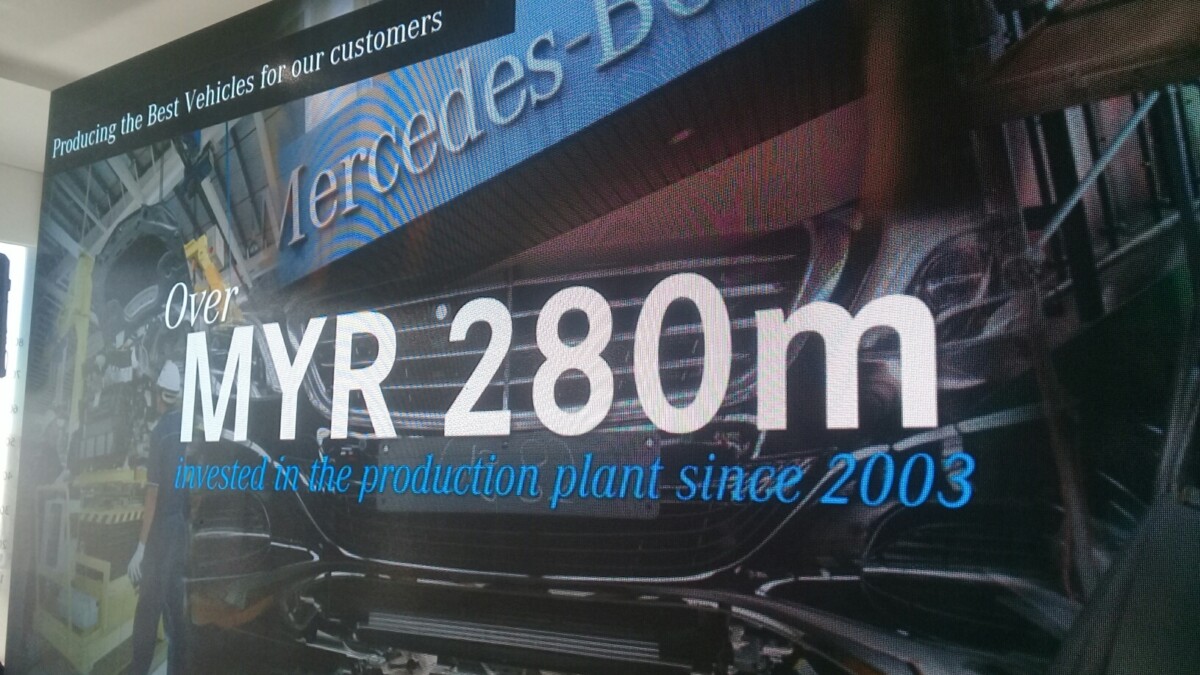

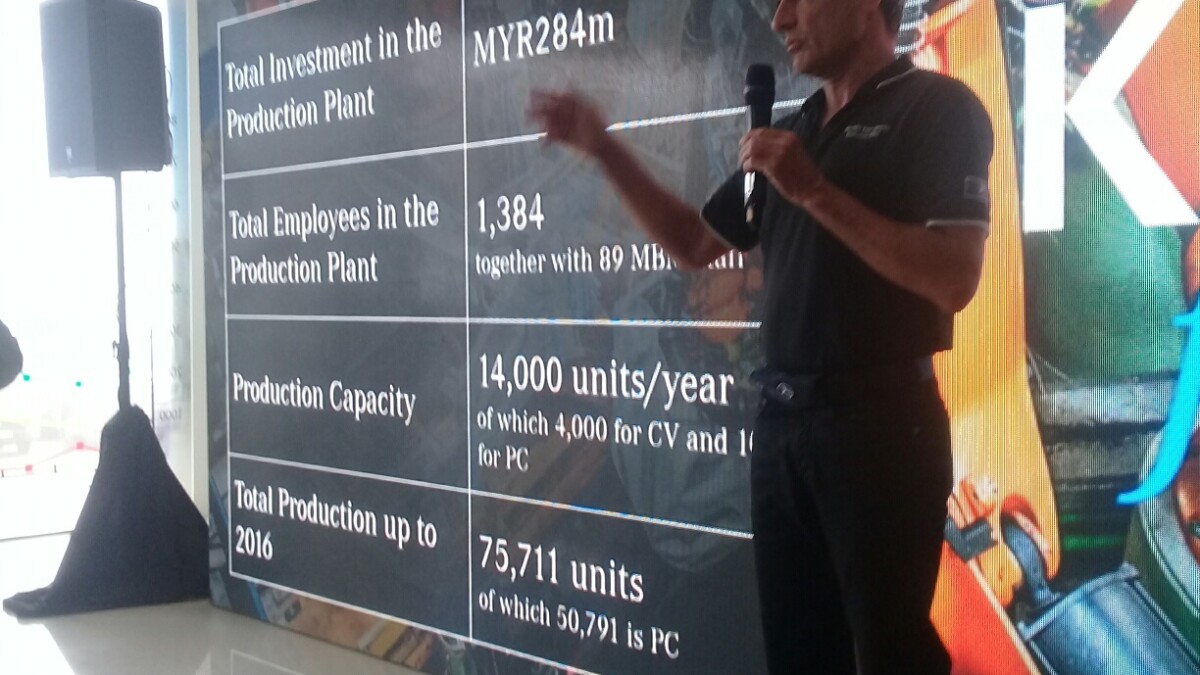

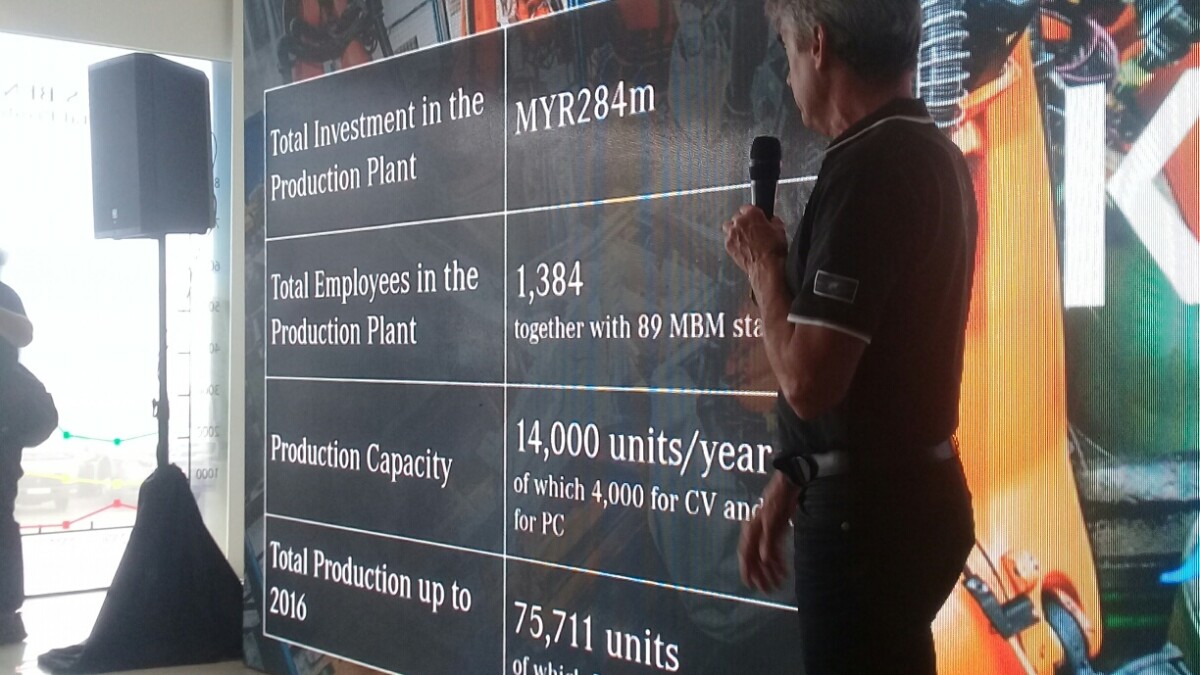

In that same vein, over one-third of MBM’s total investments have been spent on its Pekan Production Plant and Training Academy in Puchong, Selangor. The strategy demonstrates the brand’s commitment towards supporting the nation’s ambition of becoming an Energy Efficient Vehicle (EEV) hub.

“Together with its dealer network, MBM has invested over RM90 million, as at YTD 3Q 2017, to expand and upgrade its dealership network. With that, it remains the largest premium dealership network with 33 dealerships serving customers nationwide,” explained Dr Weidner.

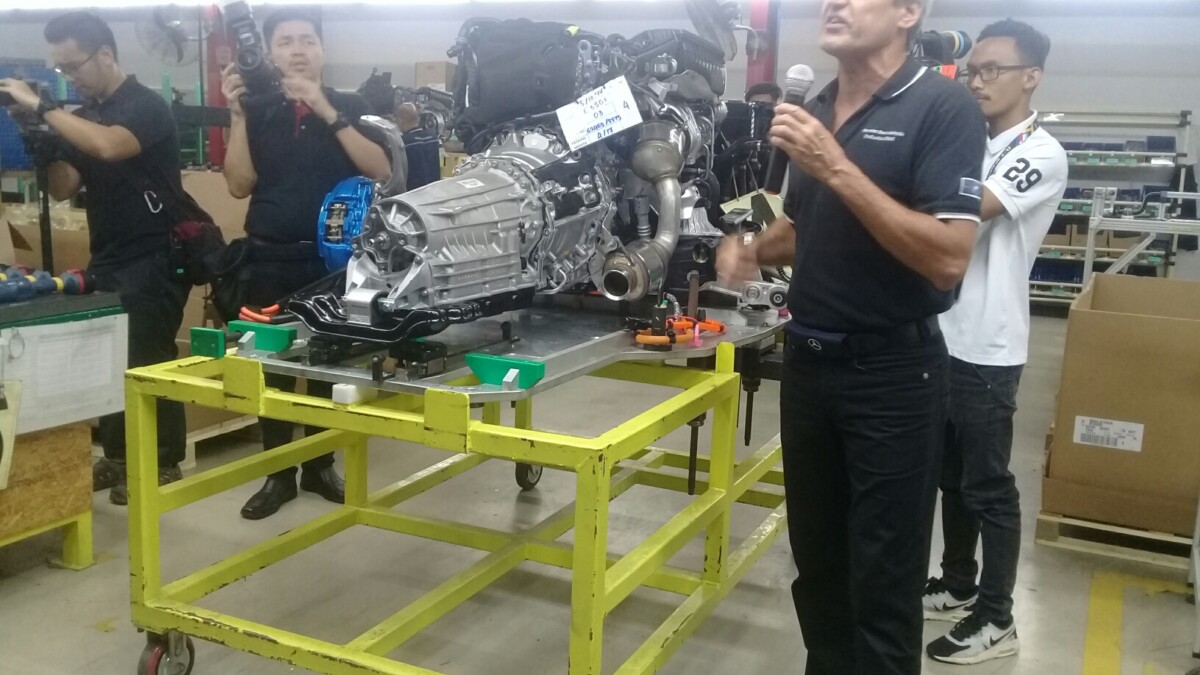

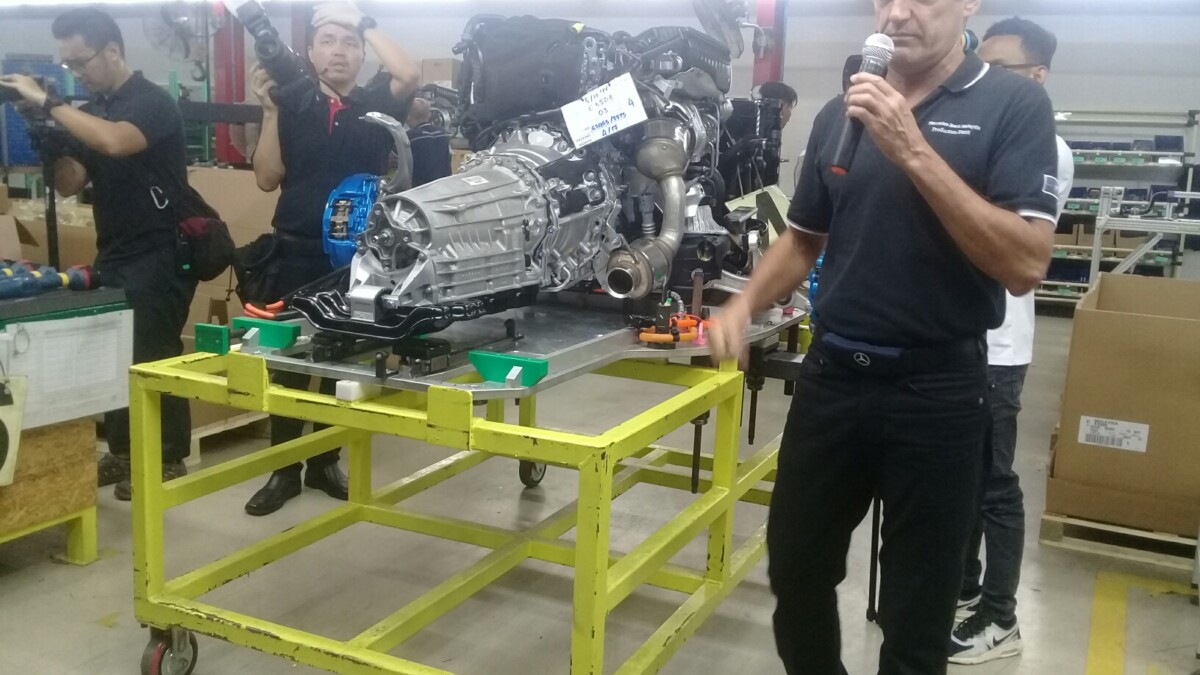

MBM hosted us, about 20 local motoring media, on a media visit at its Pekan Production Plant to help us better understand the production process of an EEV, namely the Mercedes-Benz E350e and C350e (above), which we drove up to Pekan.

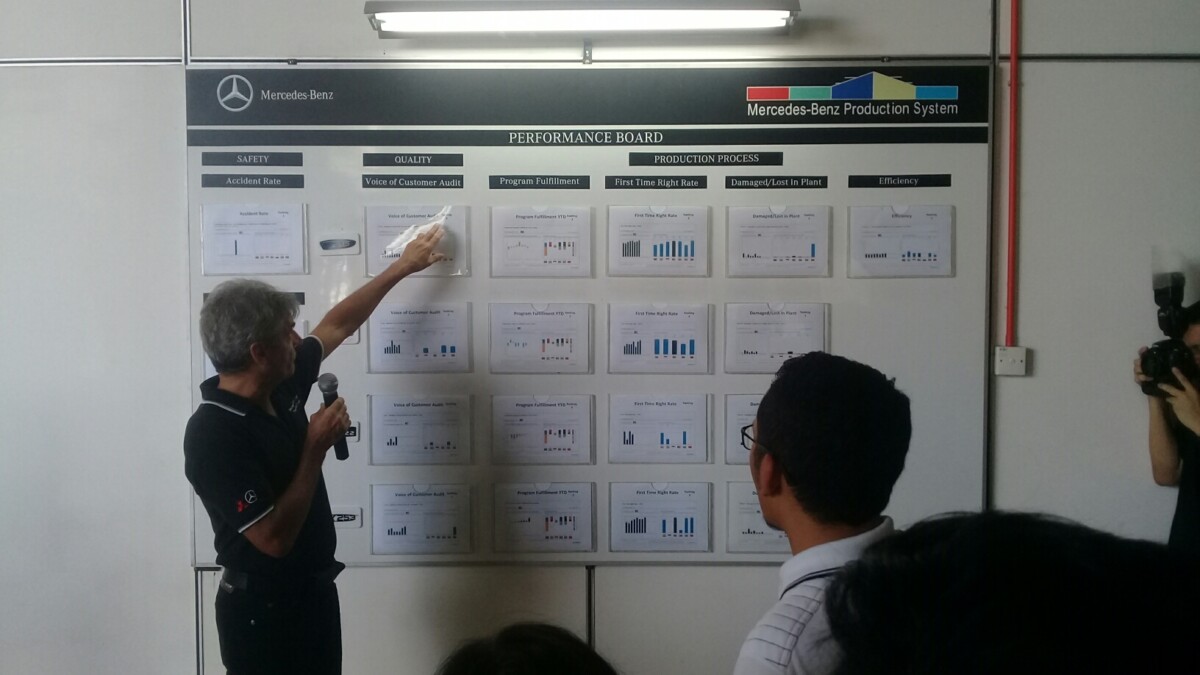

The plant tour covered the specialized requirements MBM has put in place to produce an EEV, including up-skilling staff, cutting-edge technology and provision of safety equipment, not to mention educating the Fire & Rescue Services (BOMBA) on how to deal with hybrid and PHEV cars involved in accidents.

One example we were shown, was this (above), the most “dangerous area” of the Pekan plant. In this area the high-voltage hybrid-battery system is already ‘live‘ and connected in the completed car. Nobody, not even the plant manager (above) is allowed beyond the red pylon tape…

However, if something is not right and needs to be seen to, it cannot simply be dismantled. There are specific steps that need to be taken to ensure the car doesn’t electrocute anyone touching it, which can be fatal.

A clear testament of the brand’s position as a front-runner in automotive innovation and commitment towards the nation’s EEV hub ambitions, was of course the previously reported CKD E350e preview (below), which was one of the highlights of the day.

MBM’s latest investment at the Pekan Production Plant is its paint shop which has a production capacity of 10,000 units per year.

It is equipped with a state-of-the-art robotic painting system, and is the first to use a 360-degree conveyor system in the ASEAN region. We were not allowed into the paint shop area for fear of dust contamination, so MBM prepared this video for us…

https://www.youtube.com/watch?v=6Mq2L7Jk4rI

Community wise, the plant is also helping the local economy, as MBM currently employs over 1,400 employees at the facility from the surrounding area, and enforces a requirement where 30 to 40 per cent of all its locally-produced vehicles are fitted with local content.

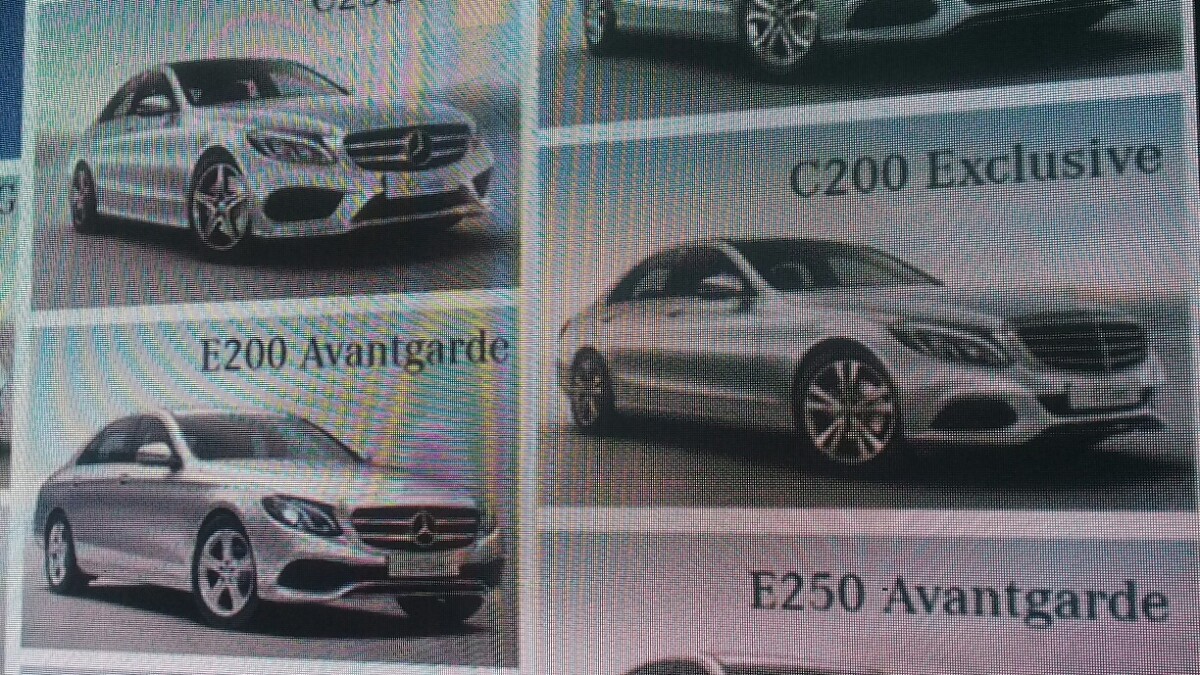

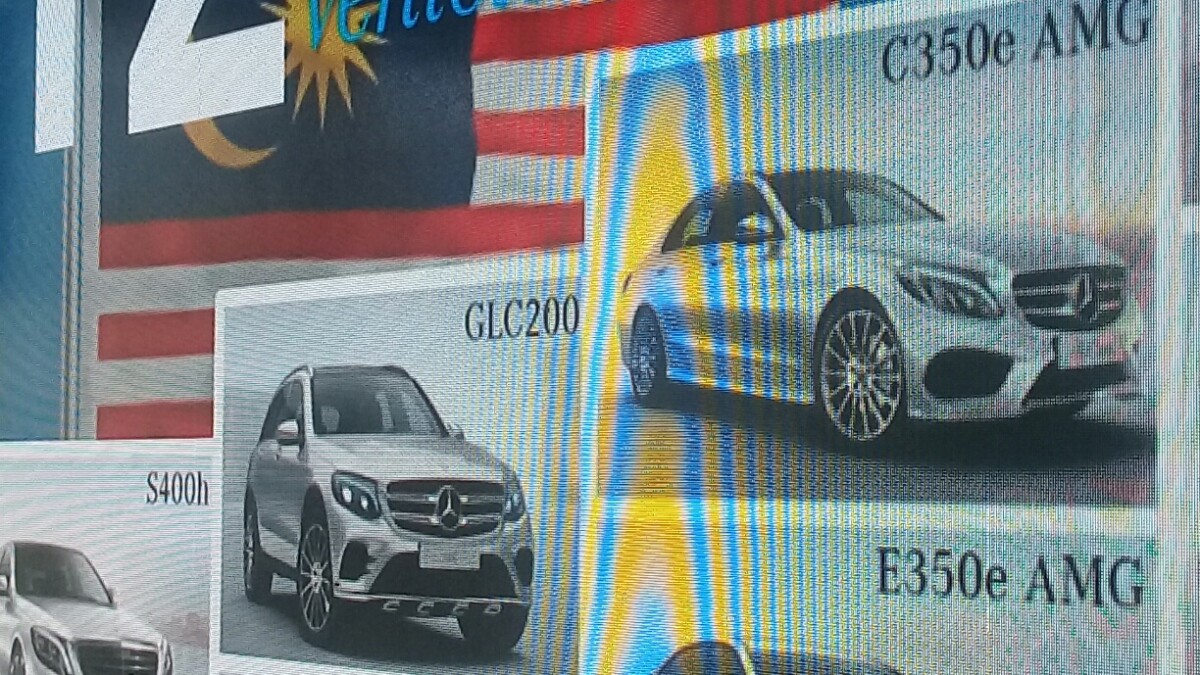

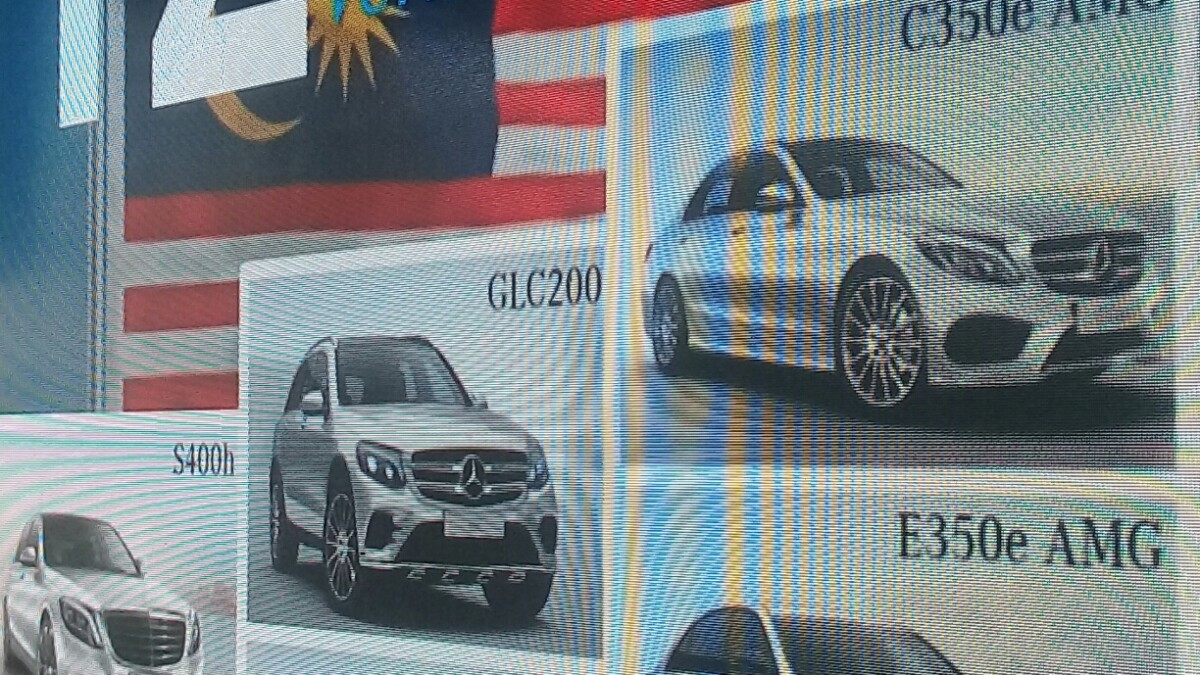

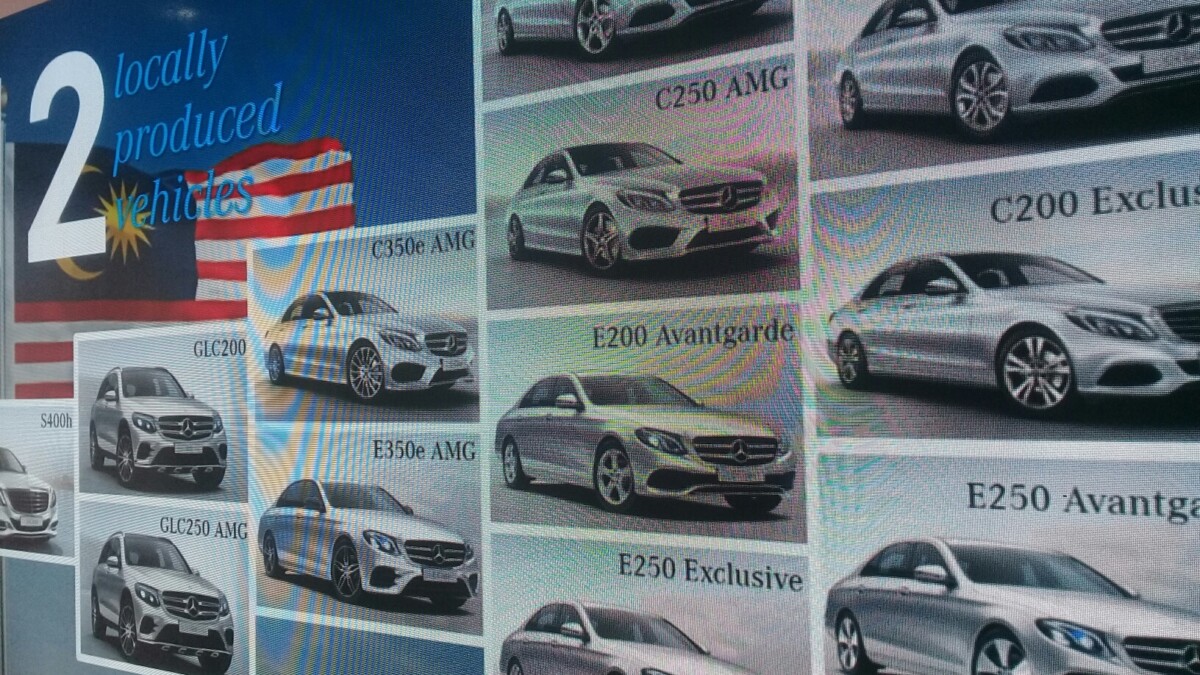

Since 2003, MBM has invested over RM280 million in the Pekan Production Plant which currently produces 12 locally assembled vehicles, the newest addition being the Mercedes-Benz GLC200.

All 12 locally assembled vehicles are classified as EEVs, out of which three are hybrid vehicles namely, the Mercedes-Benz S400h, C350e and E350e.

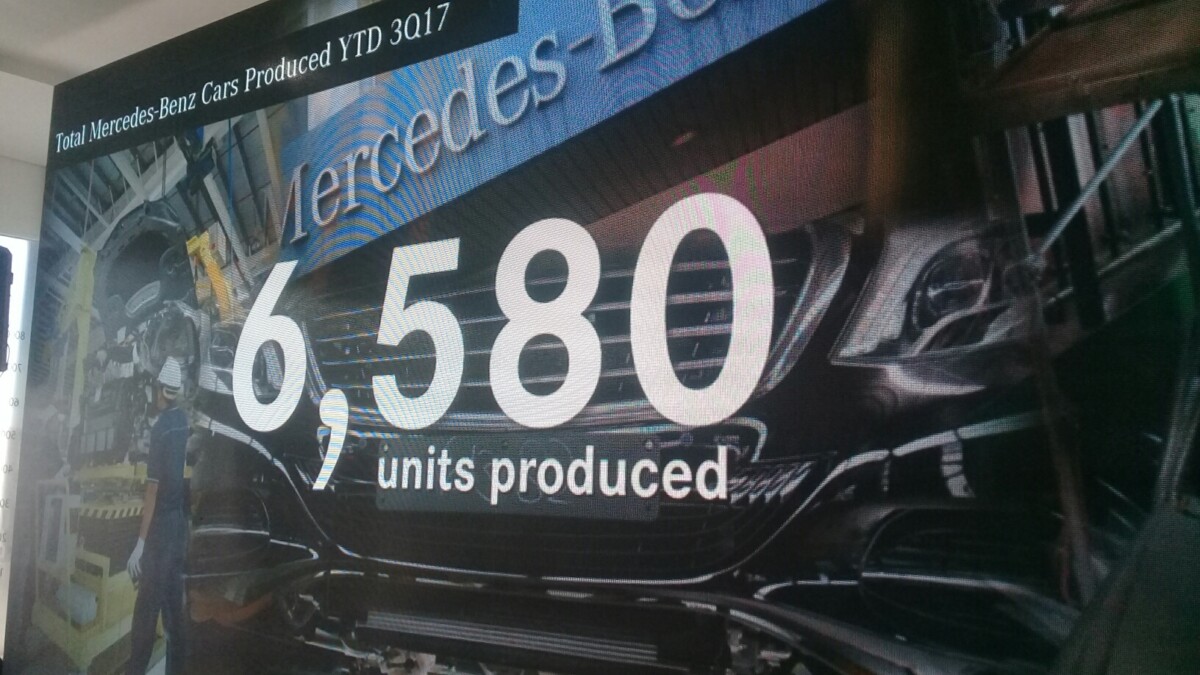

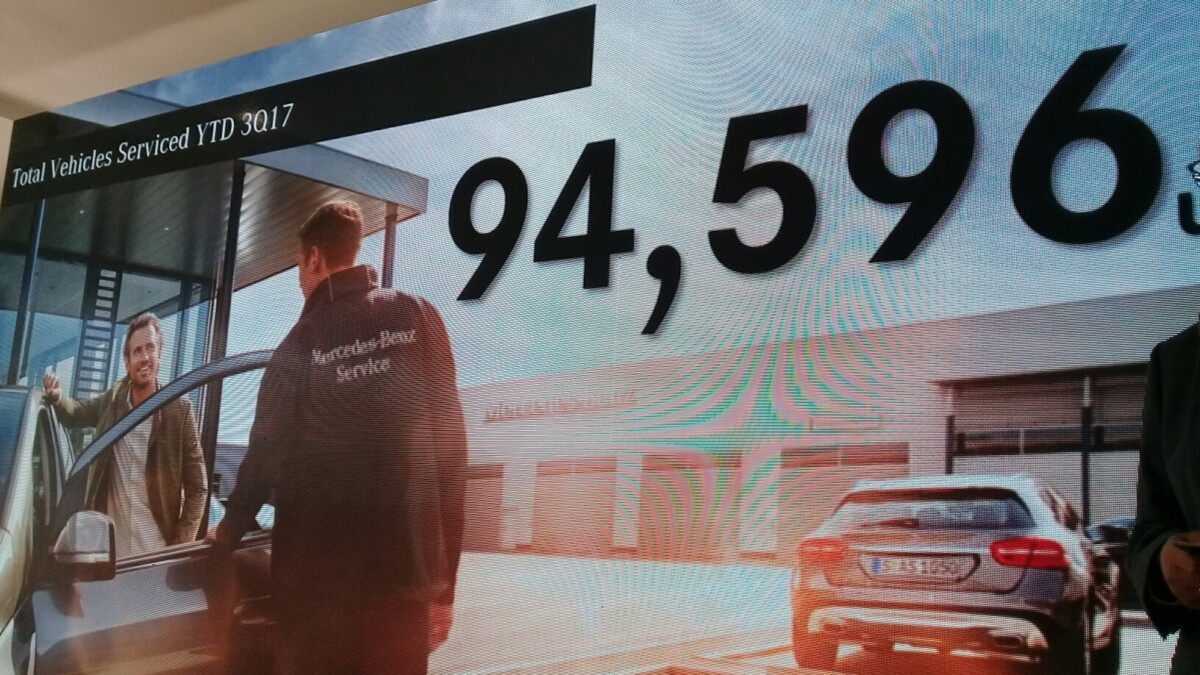

“MBM’s strategy of focusing on the Best Products and Best Customer Service continues to drive its stellar performance, helping the brand maintain its dominant lead in the premium market year-to-date (YTD). In the first nine months of 2017, MBM successfully produced 6,580 vehicles, sold 8,771 vehicles and serviced a staggering 94,569 vehicles. We are very happy with the momentum we have gained, and look forward to bringing more exciting updates to the market in the coming months,” said Dr Weidner.

MBM in 2017…

June 2017 marked the best month in history for MBM with 1,210 vehicles sold. It now leads in the premium segment, with a market share of 2.3%, YTD August 2017.

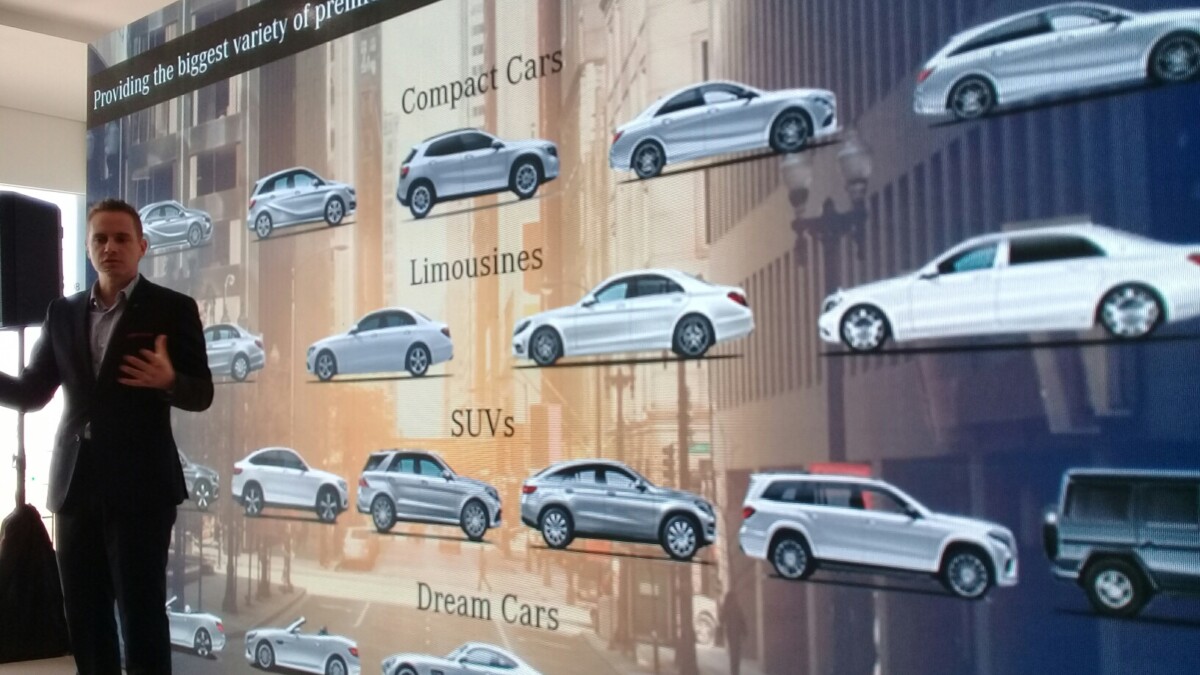

In first nine months of 2017, MBM’s sales were driven by the locally produced sedans which recorded 5,238 units sold.

The sedans comprised of the Mercedes-Benz C-Class with 3,044 units sold, followed by the E-Class with 1,891 units sold, and the S-Class with 303 units sold. This was followed closely by the Mercedes-Benz SUVs with 1,895 units sold, comprising the GLC with 1,622 units sold and GLE with 273 units sold.

Spurred by the introduction of the locally produced Mercedes-Benz GLC 200 and GLC 250, growth within this segment is expected to continue.

The Mercedes-Benz compact cars recorded a total of 1,220 units sold. The Mercedes-Benz GLA topped the compact category with 435 units sold, followed by the A-Class with 383 units sold, while the CLA sold 351 units.

The aspirational Mercedes-Benz Dream Cars, also known as the brand shapers, recorded a total of 406 units sold.

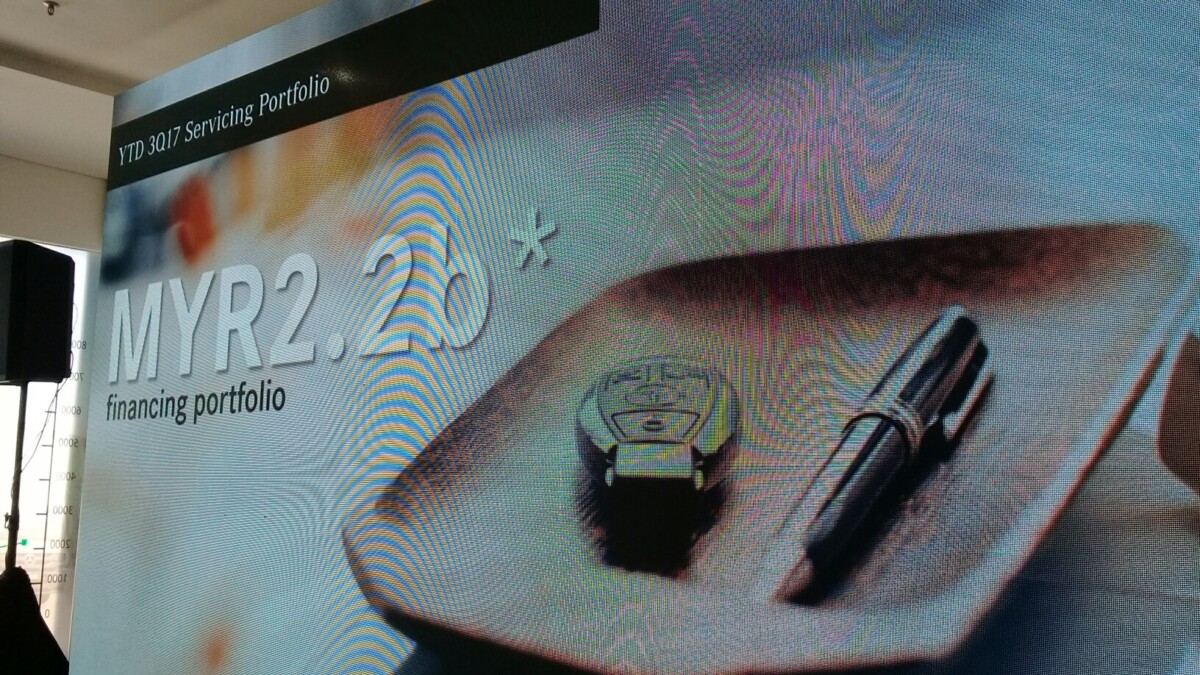

Complementing the MBM customer service journey, sister company, Mercedes-Benz Services Malaysia (MBSM) continues to provide financing and insurance solutions. YTD 3Q 2017, MBSM finances four out of every 10 Mercedes-Benz vehicles sold and has a solid servicing portfolio of MYR 2.2 billion (YTD).

With the introduction of new products like AgilityPlus and Lease2Go, MBSM aims to provide a one-stop solution for all customers further supporting MBM’s goal of Best Customer Experience.

Quite possibly for the first time ever, we were actually allowed to take photos in a production facility, so do take a moment to browse the gallery below, including the lavishly-opulent locally-assembled E350e Edition 60!

Mercedes-Benz Pekan Plant Visit, new E350e & Q3 Results Announcement Photo Gallery…

Fin…

Other posts by Chris Wee